MODULAR CONSTRUCTION

…methods will be given prevalence in the future.

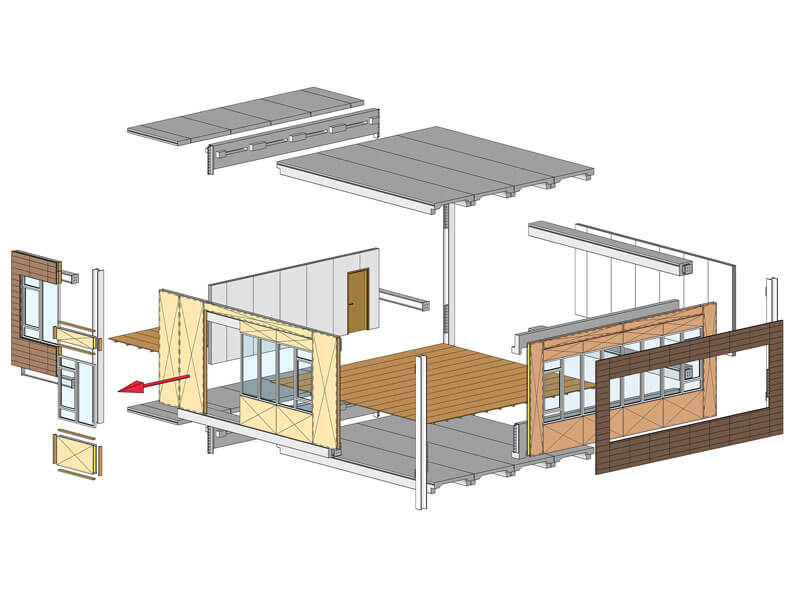

Adoption of modular construction methods can lead to improvements in productivity, enhance resource efficiency, reduce waste and minimise cost, however the true benefits can only be derived through development of the construction components from the conception stage of the project.

According to a new report from the World Economic Forum, the Engineering & Construction (E&C) industry is the largest global consumer of resources and raw materials. It uses up about half of global steel production and contributes 25-40% of global carbon emissions and 30-40% of solid waste generation. With the global population projected to grow to 9 billion by 2050, the need for rethinking the built environment within a circular economy framework, which involves shifting mindsets from designing buildings as if there was no tomorrow to envisaging their entire life cycle, is becoming ever more important. Adaptability and flexibility of buildings has been suggested as a key to tackle the challenges posed by the future. Designing multi-use spaces which can be dis-assembled and reconfigured with built-in modularity, adapting 3D printed building materials and standardised components and prefabricated construction modules can help to lengthen the building’s lifetime by 10 to 15 years and can help reduce costs by 30%, material loss by 60% and building waste by as much as 80%. Hence modular construction is one of the ways to help bring construction industry in line with a whole-system approach fit for a truly circular economy.

Atom Consultants has come up with several modular construction ideas, which have been turned into deliverable engineering standards, such as BBi600- a standardised construction method for schools. BBi600’s key benefits are:

- minimal construction waste, as standard, prefabricated modules are optimally designed

- offsite prefabrication of all materials (including steelwork) allows for rapid assembly and installation, reducing delivery times and money spent

- efficient design with pre-engineered channels and matching brackets in the cladding contributes to less tonnage, faster build and more cost savings

- optimum thermal mass is achieved by leaving the soffit of the structural slab exposed in the classrooms to assist with the climate control within the school

- immediate installation of modular services within the steel frame facilitates further reduction in delivery times

- tight project footprint allows for continuation of “live” services while construction takes place, causing minimal disruption and no health and safety issues in line with the Balfour Beatty Zero Harm Approach to Construction

We can assist clients and design teams to develop their modular approach from the earliest stages of a project to completion.

Modular SIPS for School Buildings

Originally developed for the BSF school building programme and now targeted towards the PF2 schools, a range of modular wall panel products have been developed and successfully implemented on a number of school projects with Balfour Beatty.

citizenM Tower of London Hotel

Smart and efficient: citizenM Tower of London Hotel does not disappoint.

Winton Primary School Sports Hall- London

The London Borough of Islington had a requirement for a new sports hall to be used out-of-hours by the local community and it was to be built on the roof of and existing school- Winton Primary School.

To minimise disruption to this ‘live’ site, a modular approach was adopted. All components of the build were pre-fabricated, starting from the structural steel wall and roof panels and ending with the beautiful western red cedar clad external facade.

Ark All Saints Academy & Highshore School, Southwark, London

Ark All Saints Academy and the adjoining Highshore complex mixed needs special secondary school situated in Camberwell

Cleveland Clinic – Abu Dhabi, UAE

Cleveland Clinic Abu Dhabi, on Al Maryah Island, UAE, is a unique and unparalleled extension of US-based Cleveland Clinic’s model of care, specifically designed to address a range of complex and critical care requirements unique to the Abu Dhabi population. The facilities at Cleveland Clinic Abu Dhabi combine state-of-the-art amenities and world-class service standards.